PRODUCTS: Denturists

SensAble System

With the combination of The SensAble Dental Lab System and the Bego Wironium Alloy we can provide consistent quality partial frameworks for your patients.

We believe that your talent and skills require the absolute best products and services we can provide. We are a member of the International Wironium Circle. The I.W.C. is an association with over 600 world wide laboratories that focuses on artistry, precision and quality craftsmanship.

The Benefits of partial Frameworks fabricated using SensAble's Technology

Consistent quality - fit and accuracy are at a higher level than traditional methods.

Eliminates the need for a refractory model and thus the potential for distortion.

Repeatability of design with pre-set preferences, such as clasp profiles, dimensions, and major connector thickness. All can be customized for individual preferences.

Digital approach to critical steps in the design process, such as determining the path of insertion, surveying and blocking out undercuts, provides extremely accurate results.

Working digitally, the thickness, contour and fit of our restorations are precisely controlled and easily replicated.

Allows the skilled dental technician to maintain the 'artistry' in their work using the Phantom Desktop device that provides digital design with the sense of 'virtual' touch.

System Background

Founded in 1993, SensAble Technologies evolved from undergraduate research done at MIT in the 1990s by industry pioneers Thomas Massie and Dr. Kenneth Salisbury. With 32 patents granted and over 6,000 systems installed worldwide, SensAble Technologies’ Phantom Desktop technology is being used in applications ranging from surgical simulation and stroke rehabilitation, to dental restorations, to designing toys and footwear; as well as a range of research and robotic applications.

Chromium Cobalt Frameworks

As a Bego IWC certified laboratory, Pow’s digitally designed resin wax-ups will be castin our state-of-the art Bego Nautilus CC Plus induction vacuum casting machine using exceptional Bego alloys.

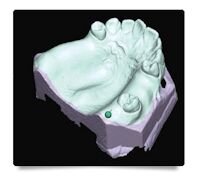

1. Scanned Model

2. Survey to identify undercuts and determine path of insertion

3. Automatically added block out

wax

4. Clasp design and placement undercuts

5. Mesh and major connector

design

6. Resin "print"of framework via rapid prototyping technology

7. Finished cast framework

Flexible Partials

Pow has the ability to design and print Flexible Partial Dentures.